Top Guidelines Of Custom Extrusion Manufacturer

Wiki Article

How Custom Plastic Extrusions can Save You Time, Stress, and Money.

Table of Contents4 Easy Facts About Custom Plastic Profiles ShownCustom Plastic Profiles - TruthsPlastic Extrusion Companies Things To Know Before You Get ThisPlastic Extrusion Profiles Can Be Fun For Anyone

Just like any manufacturing procedure, the extruded account will differ somewhat during the procedure demanding tolerances on essential dimensions. Resistances on plastic extrusions influence fit as well as feature, and the finest time to start considering tolerance needs is during the preliminary design stage. By working with Formtech early in the procedure, we can provide design for making support including tolerance needs.For a more thorough explanation regarding exactly how tolerances impact pricing, and a general resistance guide, please click here. Mass thickness is specified as the weight each volume of the plastics bought by Formtech for use in personalized extrusion applications. Bulk thickness influences flow and feed rates on the extruder, as well as variants wholesale density of the plastic will certainly create variants in dimension so it is a crucial consideration for custom extrusion production operations We discussed back stress above, and also the importance of having the ideal quantity of back stress throughout the extrusion procedure for physical property control (extrusion of plastics).

As soon as the plastic compound leaves the extrusion die in a pressed kind, the compound will certainly loosen up, or broaden a little. This is described as die swell. Die swell is material particular, suggesting for instance a plastic (PVC) material will certainly experience a different die swell than a Polyethylene or Polypropylene substance.

In the extrusion process cleaning materials out of barrels, screws and also plastic extrusion tooling requires time and also increases cost (https://www.kickstarter.com/profile/1439863340/about). For example, if material changes are being made on the line from one task to the next, this might include getting rid of and cleaning up the die, drawing the screw on the device to clean, as well as brushing out the barrel of the machine while the screws are out.

Facts About Plastic Extruded Profiles Uncovered

In fact, the purging materials are so secure they can even be left in the extrusion pass away throughout storage space, placed back on the extruder the following time the job requires to run, and started without time consuming cleaning. The typical substance will certainly press the cleanup out of the die when it leaves.

There are really 2 methods that can be utilized to accomplish this feeding process - https://www.ulule.com/k3ll3rpl4st8/#/. Initially, the material can be contained in a hopper straight over the feed-throat of the extruder as well as fed by gravity. The screws will then take in the optimum quantity of material they can with every transformation of the equipment, and this is called flood feeding.

The flights of the screw are not entirely loaded with every transformation of the equipment. This is called starve feeding of the extruder, and also offers some advantages to the extrusion technician in specific circumstances. By not loading the screw channel totally, it uses even more control to the specialist, and also removes some various other variables that can occur with flood feeding.

Custom Plastic Extrusions Fundamentals Explained

For every change of a solitary screw maker, there is some slippage back over the trips of the screw. This slippage is useful for blending of materials and also colorants, but it creates a possibility for some surging and variation with the screw change. With this being the case, differing stress as material comes off the screw can create this processing issue for the extrusion specialist.Call today or e-mail at [e-mail shielded] for more info.

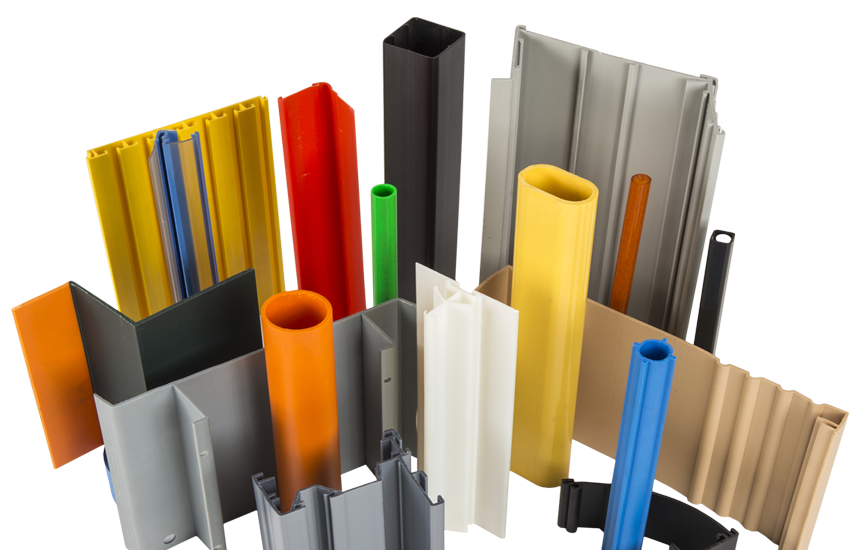

Such a selection of items and makes use of represents the large range of compatible materials and flexibility important site that the extrusion process manages in developing custom-made accounts to fulfill your precise specs. The plastic accounts developed in the extrusion procedure can be either adaptable or stiff. Both deal benefits for different usage cases (https://profile.hatena.ne.jp/k3ll3rpl4st8/profile).

Custom Plastic Extrusions Can Be Fun For Anyone

While it ultimately never ever was successful at its desired purpose, it however discovered normal use in the auto industry in various other methods, many thanks to its high fluid resistance as well as excellent securing performance. Automotive components typically made from Santoprene consist of weather seals, bumpers, cord jacketing, and also far more. Santoprene TPV's exceptional securing building likewise makes it specifically useful in building and construction, where it can be used to make window seals, tubing, electrical ports, and caster wheels (custom plastic profiles).We use advanced innovation in order to produce the specific sort of extruded product you need. We are thrilled to begin functioning with you quickly!.

Production quality products is as crucial to us as attaining the highest possible standards for customer service. At the leading edge of our solution are expert and also committed employees who meet daily challenges with ingenious concepts - plastic extruded profiles. Client email Customized profiles/ shapes Double Products Hollows Rods Tubes Angles Bindings Brackets Caps Stations Clips Edgings Insulators J-Retainers/ J-Clips Moldings Retainers Seals Sleeves Spacers Straps T-moldings Tapes Tracks Cold Temperature Level Efficiency Shade Matched Dual-Durometer Convenience of Setting Up Embossed Flame Retardant Flexible High Gloss High Temperature Performance Interlocking Locking Matte Non-Contact Food Quality Ribbed Break Fit Stiff Toughness Distinctive Weatherability Aerospace Home Appliance Air/Water/Pollution Control Automotive Building Products Concrete Building Electrical Lawn & Garden Logistics/ Transport Marine Workplace Solutions Factor of Purchase (POP) Show Numerous Solutions Can Be Managed In-Line to Eliminate Second Procedures Adhesive/Transfer Tape Application Cut to Size Cutting Drilling Embossing Heat Sealing Laminating Punching Routing Slotting Special Product Packaging Welding AIAG Automotive Market Action Group ASME American Society of Mechanical Engineers ASTM American Society for Screening and also Products DOT Department of Transportation FDA Fda FMVSS Federal Automobile Safety Criteria MIL-STD Armed Force Specifications SAE Society of Automotive Engineers UL Underwriters Laboratories ISO International Company for Standardization.

Report this wiki page